THE R8600

RADIO TEST HUB

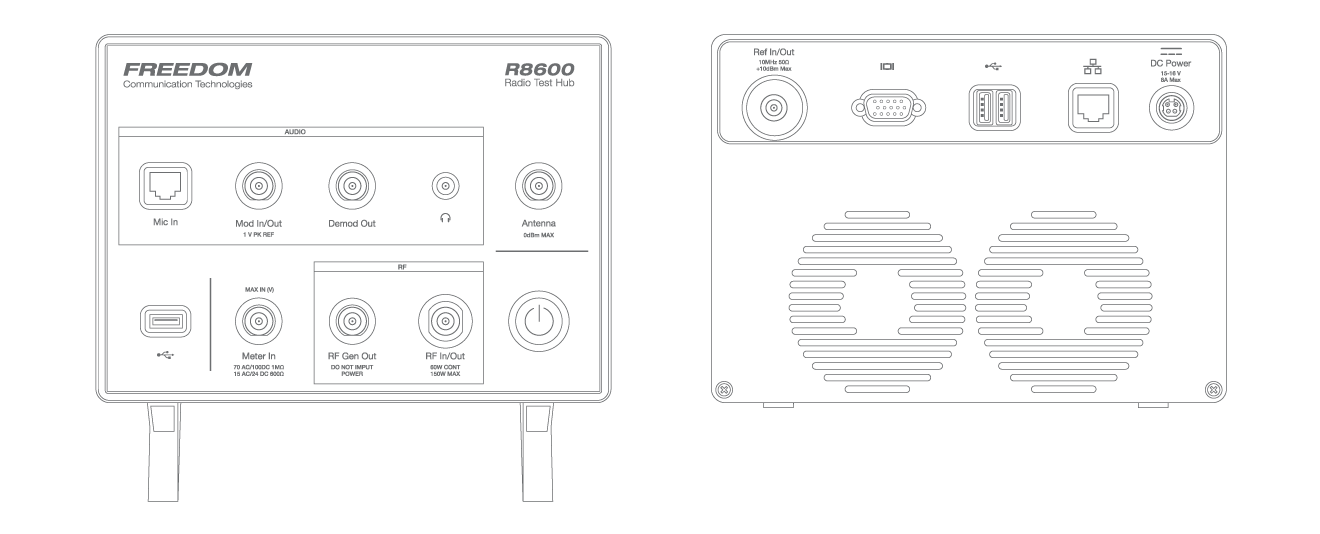

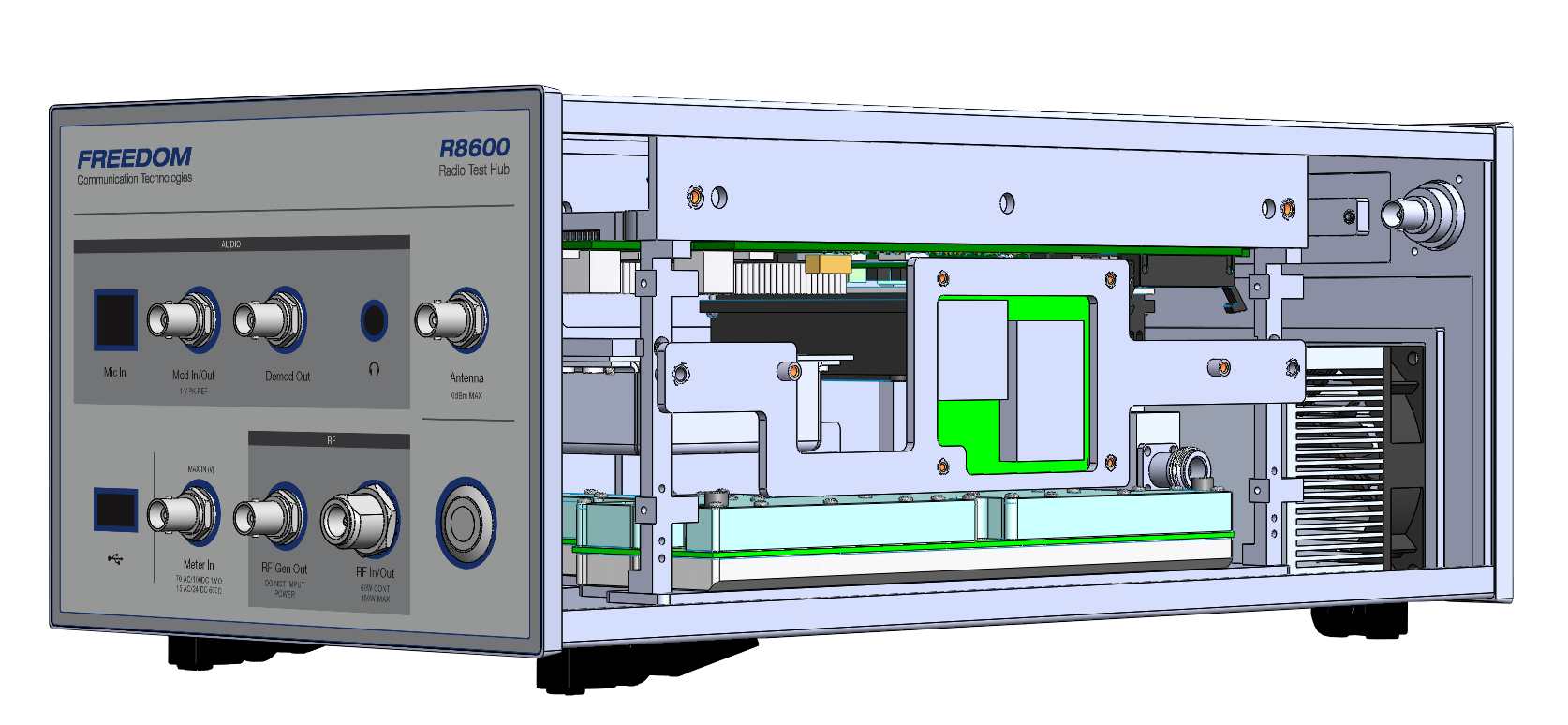

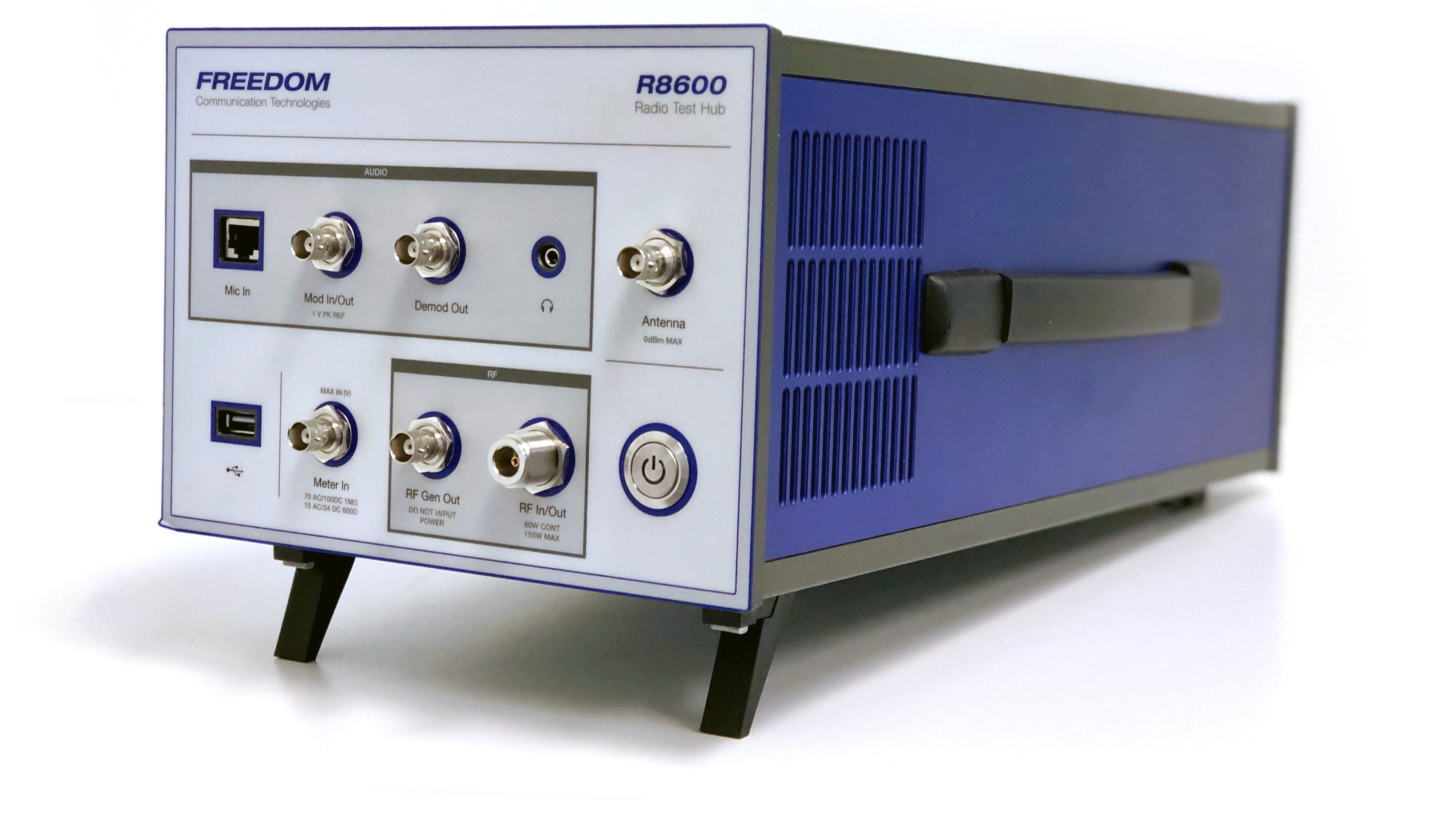

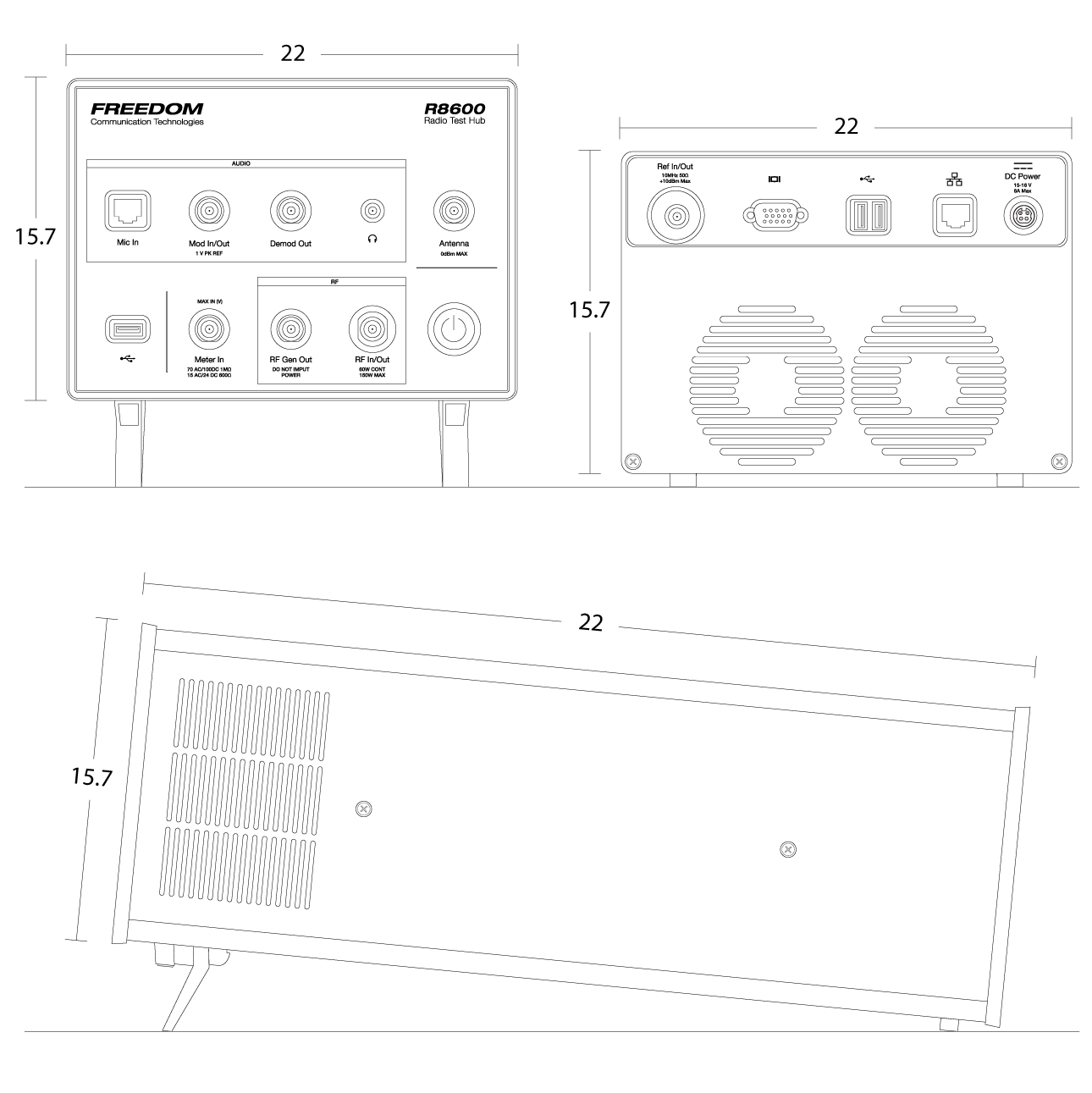

The R8600 Radio Test Hub is designed to meet the demanding requirements of RF production environments. Able to withstand 150 Watts of continuous RF power input, the R8600 was explicitly engineered to provide a cost-effective solution for 24/7 manufacturing use. Once deployed, it requires minimal operator intervention beyond making the physical RF connections.

The Radio Test Hub provides reliable, easy-to-operate testing for manufacturers of LMR radios and other RF devices. It operates without an embedded display to make efficient use of manufacturing rack space in an ATE environment, and uses our native Monitor & Control language. Powered by our Software Defined Radio architecture, the R8600 is ideal as both an upgrade to enable testing of modern digital radio technologies and for the production of analog radios and RF devices.

Two units can fit side-by-side in a standard 19” rack. The units stand less than 4RU high. A backpack accessory is also available for portable use.

INSTRUMENTS

Measurement

Spectrum Analyzer

Signal Strength Meter

Broad & Narrow Band

Power Meters

Measurement Receiver

Audio Counter

Modulation Scope

AC/DC Voltmeters

Distortion Meters

AM Modulation Meter

FM Deviation Meter

Frequency Error Meter

Signal Generator

RF Signal Generator

Audio Signal Generator

Protocol Generator

Special Instruments

Tracking Generator

Cable Fault Locator

Return Loss/VSWR bridge (opt.)

Display

Spectrum Analyzer

SINAD Meter

Oscilloscope

Distribution Plot

Eye Diagram

Constellation Display

Power Profile

Protocols

DMR

TETRA SubscriberTest

TETRA TMO and DMO

TETRA Base Station

NXDN Conventional

P25 Conventional

P25 Trunking

PTC: Positive TrainControl

dPMR

NCDN Type C Trunking

CONTINUOUS RF POWER INPUT.

24/7 MANUFACTURING USE

The R8600 Radio Test Hub is designed to meet the demanding requirements of RF production environments. Able to withstand 150 Watts of continuous RF power input, the R8600 was explicitly engineered to provide a cost-effective solution for 24/7 manufacturing use. Once deployed, it requires minimal operator intervention beyond making the required physical RF connections.

MANUFACTURING

AUTOMATION

The Radio Test Hub provides reliable, easy-to-operate testing for manufacturers of LMR radios and other RF devices. It operates without an embedded display to make efficient use of manufacturing rack space in an ATE environment, and uses our native Monitor & Control language. Powered by our Software Defined Radio architecture, the R8600 is ideal as both an upgrade to enable testing of modern digital radio technologies and for the production of analog radios and RF devices.

EASY INTEGRATION INTO MANUFACTURING LINES.

The unit’s software upgradability enables the radio manufacturer to standardize test equipment across multiple product lines, simplifying new product introduction and reducing associated costs. Users can also control the R8600 via any standard test-based Telnet application, using the provided remote control command set.

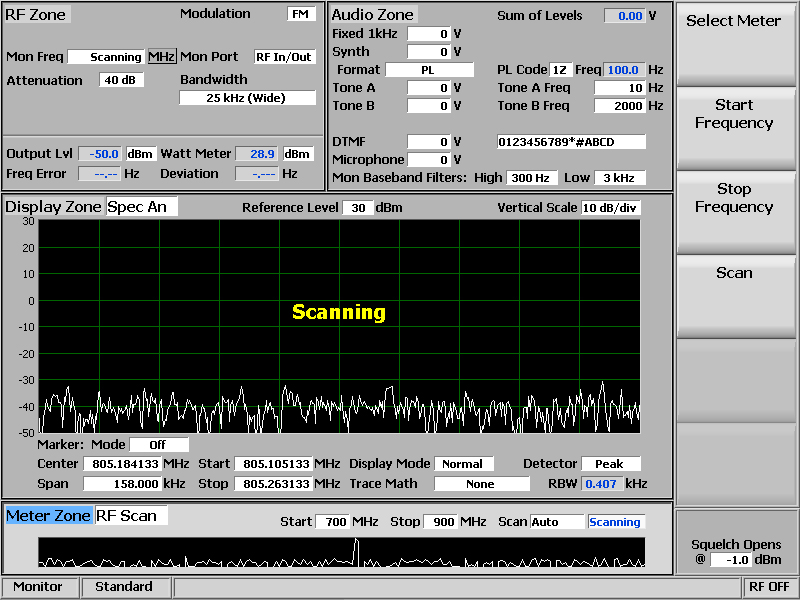

AUTO RF SCAN

The new “Auto” mode of the RF Scan meter scans the user specified frequency range to find the most powerful signal that exceeds the selected squelch threshold, for example, to rapidly determine a radio channel or sequentially test different radios with minimal effort. Locking to the signal in a wide frequency range will now complete quickly with both the new “Auto” mode as well as the existing single search mode.

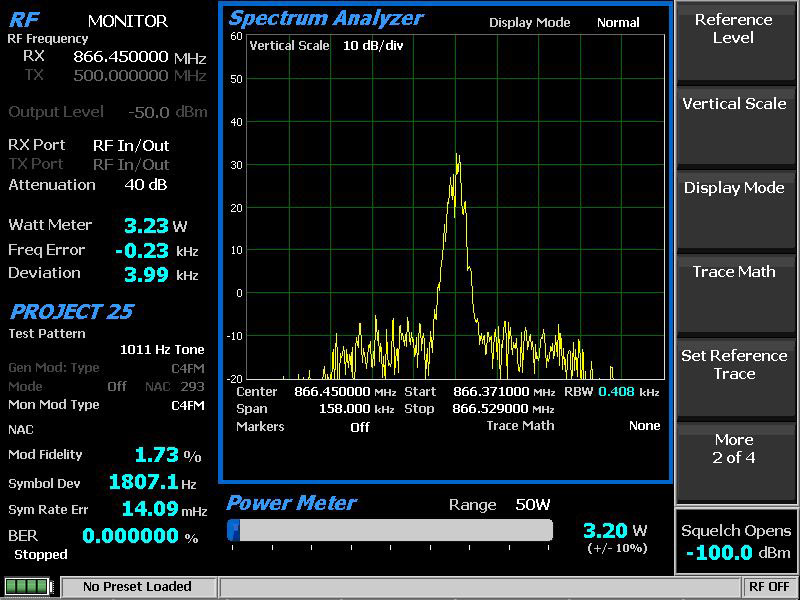

SUPERIOR SPECTRUM ANALYZER

The R8600 comes equipped with a superior spectrum analyzer with a noise floor well below -140 dBm at narrow spans, super-fast signal acquisition, 4 markers (2 standard), and an available variable vertical scale down to 1 dB per division.

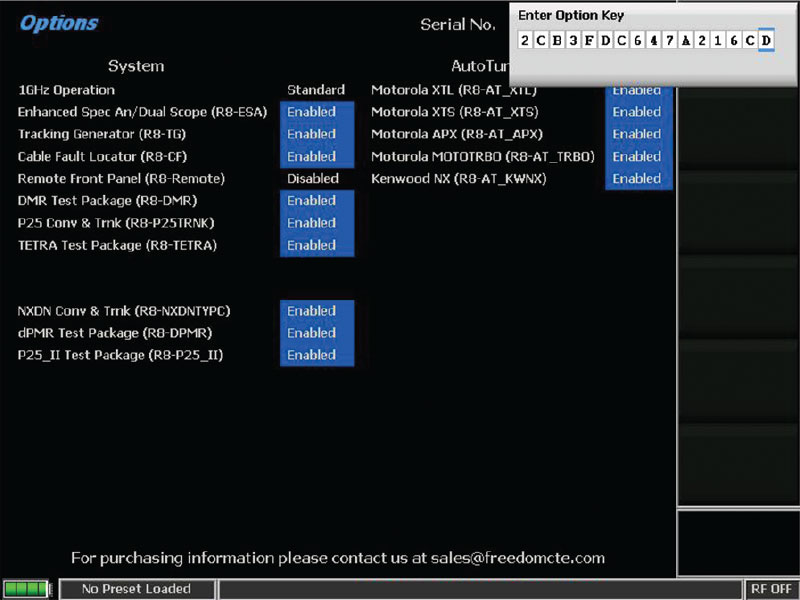

EXPANDABLE AND UPGRADABLE

The software-based architecture of the R8600 lets you add software options and upgrades locally.

So if your needs change down the line, simply order the feature or protocol you need and enable it by entering a 16 digit option key using the front panel keypad.

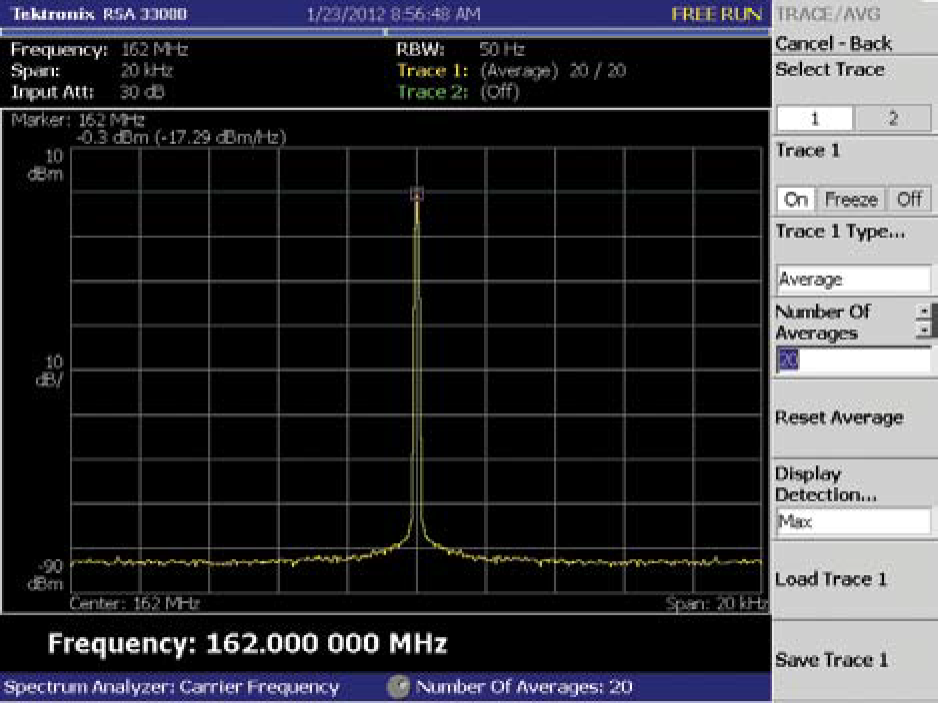

LOW PHASE NOISE AND MONITOR & CONTROL INTERFACE

The M&C consists of proprietary commands as well as support of IEEE standard equipment ID query for automating manufacturing test processes and procedures. This, along with the exceptional phase noise performance of the signal generator, makes it perfect for manufacturing and other high-performance applications, enabling significant reductions in capital costs.

SPECS

| Weight: | 18 lbs | |

| Dimensions: | 6.2” H x 8.7” W x 17.3” D | |

| Operating Temperature: | 0º to 50ºC | |

| Shock and Vibration Rating: | MIL-PRF-28800F, Class 3 | |

| TCP/IP Command Methods: | R8000 scripting language | |

| Remote control utility (provided) | ||

| RF Input: | 150W continuous (24/7) | |

| Timebase Stability: | Aging: ±0.1ppm / year | |

| Temperature.: ±0.01ppm | ||

| Frequency Range: | 250kHz - 1GHz; Optional to 3GHz | |

| Displayed Average Noise Floor: | -140dBm | |

| Residual FM: | 4Hz, 300Hz to 3kHz (<1GHz) | |

| 5Hz, 300Hz to 3 kHz (> 1GHz) | ||

| Phase Noise (20kHz Offset): | -95dBc/Hz max < 1GHz (15° - 35°C) | |

| -93dBc/Hz max all freqs. (0° - 50°C) | ||

| Power Meter Range | 0.1W - 150W across all frequencies | |

| Presets available: | >1000 | |

| Optional Test Modes: | DMR (MOTOTRBO™), NDXN, NXDN Type C Trunking, dPMR, P25 Phase 1 (Conventional and Trunked), P25 Phase 2, TETRA handset, PTC (ITCR) | |

| Warranty: | 3 Years Standard | |

| 5-year service plans optional |

FREEDOM has a variety of technical documents for your reference. These documents are designed to provide you with the necessary information about our products: Brochure, Datasheets, Operators Manuals, User Guides, App Notes, White Papers and practical guidelines